Need help? We're here!

(888) 312-8812 Login SignupHow Air Brakes Work

June 14, 2021

One of the unique characteristics of a modern heavy duty vehicle is the air brake system. Unlike lighter passenger vehicles that rely on hydraulic brakes, trucks, buses, and other heavy vehicles are equipped with air brake systems, with many countries requiring them by law. That is because air brakes have unique properties that offer many significant benefits to heavier vehicles.

In this guide, we'll break down how air brakes work and what advantages they bring to heavy duty vehicles.

What are air brakes?

Also known as pneumatic brakes, the air brake system uses compressed air to push the brake lining into the brake drum, forcing the wheel to slow down and stop. It’s similar to hydraulic brakes in principle, which uses pressurized hydraulic fluid instead of air to move the brake lining. However, that’s where similarities stop as air brakes rely on a system of unique components to convert outside air into a force powerful enough to stop a truck’s wheel from moving.

Air brake parts

A modern air brake system consists of several components, including pumps, actuators, and sensors that vary in design and function depending on the manufacturer. Among the key elements that all these systems share include:

- Air compressor: It serves as the pump, which draws and compresses air into the storage tank. The engine normally powers it through a belt drive.

- Air compressor governor: This is a device that controls the pressure of the air pumped into the storage tank by the compressor.

- Air dryer: It removes moisture content from the air, preventing harmful water condensation from forming inside the brake lines.

- Air storage tank: This serves as the reservoir that stores the compressed air from the compressor. It is designed to always have enough compressed air for the brakes to be applied multiple times and prevent complete brake failure if the air compressor fails.

- Brake pedal: This refers not just to the pedal the driver steps on but the entire mechanism that engages the brake piston into the brake pads.

- Brake cylinder: Also known as the brake chamber, this device uses a cylinder and piston to push the pads into the disc or drum to stop the vehicle. To ensure reliable performance, technicians must follow best practices for air brake chamber installation and replacement during every service.

- Brake valve: This valve is responsible for ensuring pressure in the brake lines and cylinder is regulated so that it builds according to the motion of the brake pedal.

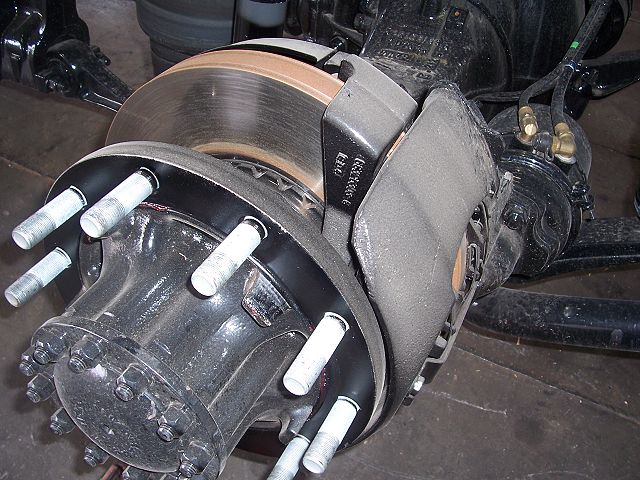

- Brake drum/brake disc: This device comes in frictional contact with the brake pad and drum lining and forces the wheel to stop or slow down.

- Dirt collector: Placed inside the brake pipeline, this device removes dirt or other contaminants from the air before reaching the brake valve.

How do air brakes work

When the engine starts, the brake compressor starts to pressurize the air. The compressor governor then sends this compressed air at a set pressure to the air storage tank. The tank normally has some amount of air from the previous cycle, so even if the engine is shut off, the brakes will still function as normal.

Once the driver steps on the brake pedal, the brake valve opens and redirects compressed air from the reservoir to the brake lines and into the brake cylinder. The pressurized air then pushes against the piston inside the cylinder, forcing it to move away from its original piston. This movement causes the actuators inside the brake drum to expand, pushing the brake pads in an outward direction until it comes in frictional contact with the rotating drum brake lining.

Eventually, the friction between the brake pads and lining causes the wheels to decelerate. Similarly, the driver releases his or her foot from the pedal, the piston pulls back into the cylinder and cancels out the friction and slow-down effect.

Advantages of air brakes

Because of how they function, air brakes offer several benefits to heavy commercial and multi-trailer vehicles over conventional hydraulic brakes:

- Air brakes run on an inexhaustible supply of air, so they won’t “run out” of fluid in the same way as hydraulic brakes. As a result, even minor leaks will not automatically result in brake failure.

- While hydraulic fluid use in hydraulic brakes is nearly incompressible, air can be compressed and store potential energy in the process. This makes them viable for storage in an air tank as they will retain sufficient force to operate the brake chamber and stop the vehicle should the compressor fail.

- Air brakes remain effective even with considerable leakage in the brake lines. Modern air brakes are also designed with a fail-safe system that maintains truck safety even if a leak occurs.

- Compressed air can also be used for accessory applications that hydraulics are not suited for, such as air horns and seat adjusters.

- Air hose couplings are easier to install and maintain than those used hydraulic lines. As a result, the risk of air contaminating hydraulic brake lines is eliminated, so there’s no need to “bleed” air brakes when they are being serviced. Similarly, air brake circuits on trailers are easier to attach and remove compared to their hydraulic counterparts.

Air brake maintenance

Arguably the biggest disadvantage of air brakes is that they are expensive and time-consuming to maintain, particularly in their first five years of operation. Air brakes are especially prone to moisture damage, which is why they are fitted with specialized air dryers and filters. Should these filters fail, condensation will form inside the brake lines, leading to corrosion or ice buildup in colder climates. To avoid these issues, many professional drivers emphasize preventive maintenance of air brake systems to reduce wear and improve long-term reliability.

Modern air brakes are designed with durability in mind, but they still require periodic attention. Along with regular moisture drainage, staying ahead of common brake issues like air leaks or pressure drops will help you identify problems before they lead to a full system failure. Like hydraulic systems, air brakes also rely on shoes, pads, and drums that naturally wear out from constant use.

Thankfully, these systems are now maintenance-friendly and can be quickly serviced using aftermarket parts. Whether you are performing a routine inspection or a complete overhaul, using high-quality semi-truck brake system maintenance and replacement parts ensures your vehicle remains compliant with industry standards. Here at FinditParts, we offer a wide range of OE and aftermarket components—from compressors to bushings—of outstanding quality. Browse our catalog today and save!