Need help? We're here!

(888) 312-8812 Login SignupWhy Brake System Maintenance Prevents Major Road Accidents

September 04, 2025

Brakes don’t give second chances. If they fail on a loaded heavy-duty truck, things can go south quickly. It’s not just about stopping power either. A brake system that isn’t pulling its weight puts the whole rig and everyone on the road at risk. Anyone who’s ever had to white-knuckle a downgrade or sideline a truck because something felt off knows the value of solid, well-kept brakes.

One driver in Arizona shared how a neglected brake chamber ended in a runaway trailer on a sharp descent. No one wants to be the guy on the other end of that phone call, explaining why the freight’s not going to make it and why there’s cleanup being done on a mountain pass. Brake issues don’t wait for a shop visit. They show up exactly when it’s least convenient. Staying ahead of wear and tear is one way to keep your trucks and your record clean.

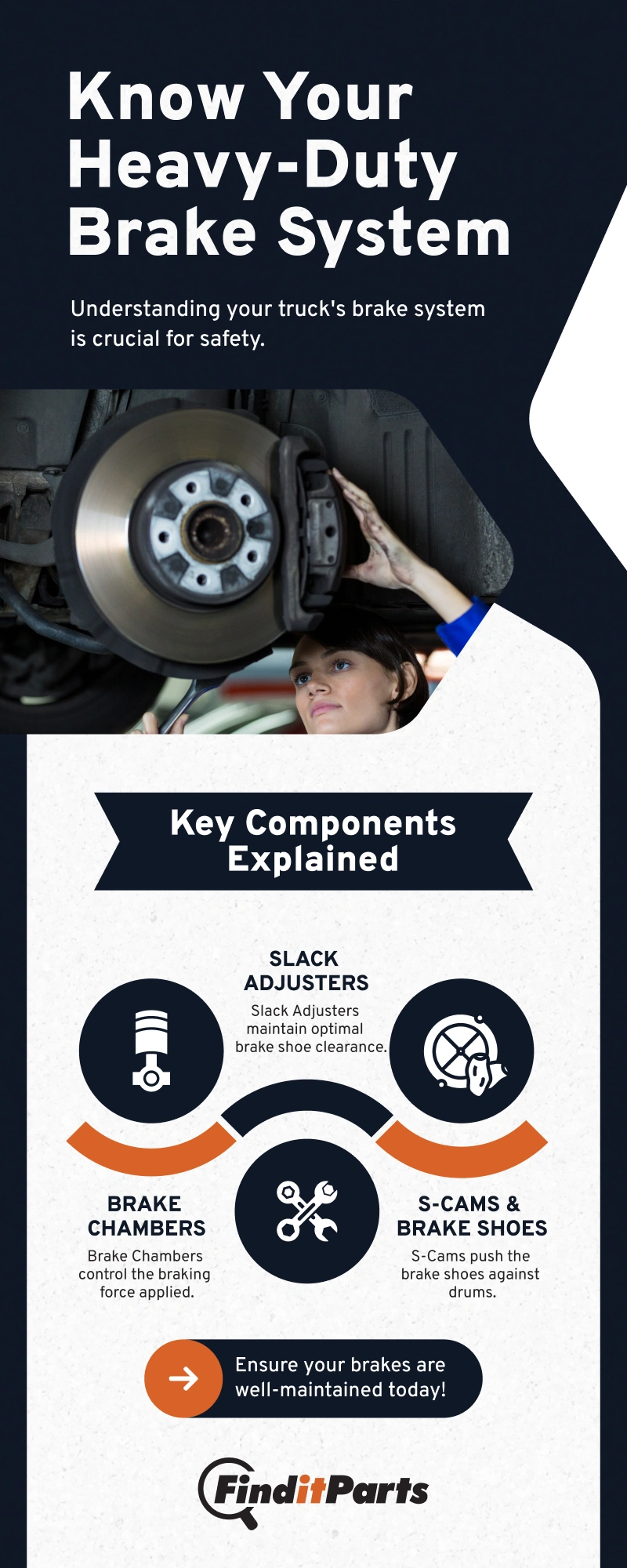

Understanding Brake System Components

To prevent big problems, it helps to know what you’re working with. A brake system for a heavy-duty truck isn’t just one or two parts. It’s a setup made from several pieces that all need to do their job without skipping a beat.

Here are some of the key components that make the system work:

- Brake chambers: These convert air pressure into mechanical force. If one goes bad, your stopping distance gets longer fast.

- Slack adjusters: These pieces help keep proper tension in your brakes. Automatic or manual, they need to be set right or your brake balance will be off.

- S-cams and brake shoes: These parts create the force that presses against brake drums. If they’re uneven or worn, stopping power drops, and drum damage becomes likely.

- Air lines and valves: The backbone for air distribution. Any leaks or blockages can keep the whole system from working properly.

- Drum or disc brakes: Most heavy-duty trucks rely on drums, but some use hydraulic discs up front. Either way, they have to be in good shape for reliable stopping.

It’s a pretty simple recipe. If one part in that mix fails or works harder than it should, you lose efficiency, wear builds up quicker, and accident risk spikes. Every component depends on the others. That’s why treating your brake system like a single unit, not just a bunch of parts thrown together, makes all the difference.

Warning Signs Of Brake System Issues

Not all brake problems show up screaming. Some creep up quietly. The trick is catching them before they turn your next run into a hazard. When something shifts in how the brakes handle, it’s best to pull over and check it out, not wait until inspection day.

Here’s what to watch for:

- Spongy or slow pedal response

- Pulling to one side when braking

- Grinding, squealing, or clunking sounds

- Air leaks or a constantly running compressor

- Excessive brake dust or uneven tire wear

These signs mean something isn’t right, whether it's a misadjusted slack arm, low brake lining, or a stuck caliper. The longer they're ignored, the more expensive it gets. Taking action early keeps the problem small and helps prevent a mess on the road.

Some mechanics say, if you hear it, smell it, or feel it, it’s already overdue. That holds up. Brake issues leave clues. And seasoned drivers often spot them before things get dangerous. Regular walk-arounds and brake tests give you the upper hand. It's way better than handing over your rig to a tow truck after something gives out downhill.

Maintenance Best Practices For Brake Systems

Brake maintenance doesn’t need to be complicated, but it does need to be consistent. A few extra minutes during downtime can mean the difference between a smooth haul and a bad day on the shoulder waiting for a wrecker. Whether you're running a single truck or overseeing a full fleet, stick to a checklist that covers all the usual suspects.

Here’s a weekly and monthly brake maintenance checklist that many techs and operators rely on:

- Check linings and drums for wear. Any significant scoring or grooves could be signs of incorrect contact or overheating.

- Examine the brake chambers for corrosion, air leaks, or damaged diaphragms.

- Make sure slack adjusters are functioning correctly and not out of stroke. Measure the pushrod travel if needed.

- Inspect hoses and air lines for cracks, kinks, or rub-through spots.

- Air dryers and tanks should be drained regularly, especially in humid or wet conditions. Moisture in the air lines can turn into ice once the temperatures dip in late fall.

- Look at brake pads for uneven wear. That could point to a problem in caliper function or rotor condition if running disc brakes.

- Confirm proper brake light operation during the walkaround. A working brake system won’t matter if nobody behind the trailer sees a stop coming.

Tight schedules and long runs can make it tempting to push inspections off, but that’s a losing bet. Brake parts wear differently depending on usage, load, terrain, and even time of year. Brakes that held up fine in cooler weather might act up when temperatures spike mid-summer, especially with heavier hauls going cross-country. Regular inspection keeps small issues from stacking up into something that costs time, cash, and credibility.

The Role Of Quality Parts In Long-Term Safety

Replacing worn or failing brake components is part of the job, but what they’re replaced with matters. Cheap, off-spec parts might seem like a quick win on cost, but those savings disappear fast if they lead to bigger failures down the line. Quality parts that meet OE specs help ensure the braking system holds up under pressure, especially during mountain descents or in heavy city traffic.

That said, even good parts won’t do much if they’re mismatched or installed improperly. Sourcing parts that fit the exact truck make and model makes installation quicker and helps you avoid performance gaps. For example, trying to stretch linings beyond their load rating or running undersized chambers on heavier axles causes more wear on the other components. It’s a domino effect.

Choosing the right part the first time not only helps meet inspection standards but keeps the whole rig safer for the long haul. Over time, using compliant and spec-matched components cuts down how often you’re sidelined for sudden brake fixes or DOT flags.

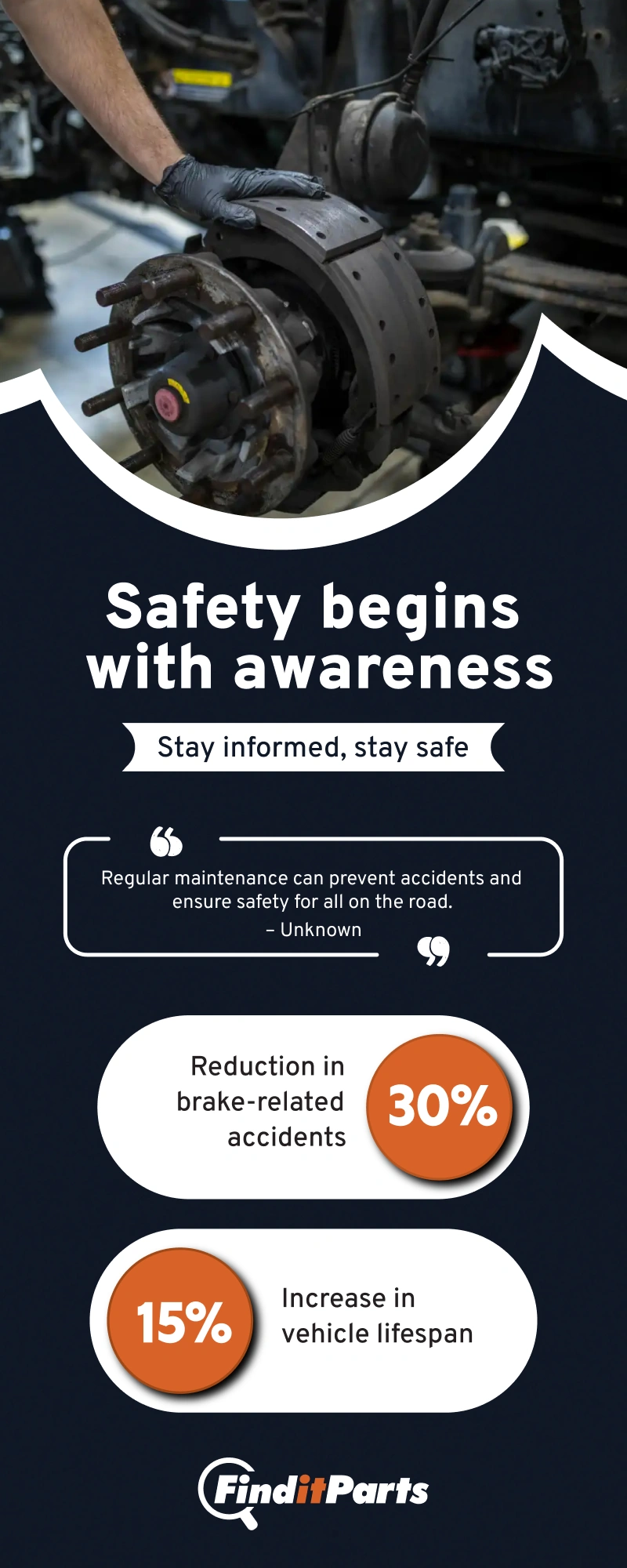

Why Consistent Brake Maintenance Is A Lifesaver

At the end of the day, keeping brakes in top shape is about more than passing inspections or avoiding costly repairs. It’s about safety for you, your crew, and everyone else sharing the road. Every loaded rig is carrying thousands of moving parts and maybe even more in cargo. The one system that stands between that load and a full-speed stop is the brakes.

It’s easy to get caught up in day-to-day ops, but taking the time to keep up with your brake system pays off where it counts. Trucks that get seen regularly are the ones that make it through summer hauls, sudden storms, or long stretches with fewer problems. Avoiding downtime due to neglected brakes means less worry, fewer phone calls from dispatch, and more confidence behind the wheel.

Bad brakes don’t give you many warnings. They just fail. Understanding how the pieces work, spotting early signs of trouble, and replacing parts with ones that do the job right all come together to help keep drivers safer and trucks rolling. Regular brake maintenance isn’t just smart. It’s a lifeline.

Regular brake maintenance is a must for safety and peace of mind on the road. When you're ready to keep your rig in top shape, trust FinditParts Inc. for reliable solutions. Explore our selection of heavy-duty parts for trucks to ensure your vehicle stays roadworthy and compliant.