Need help? We're here!

(888) 312-8812 Login SignupTroubleshooting Common Electrical Problems in Heavy-Duty Trucks

September 04, 2025

Nothing grinds your day to a halt like an electrical problem in your truck. One minute you're on the road, and the next, you're stuck with a dead starter or flickering lights, wasting time you simply don’t have. Whether you're the one behind the wheel or the one running the shop, electrical problems aren’t just annoying—they keep your truck from doing what it needs to do.

The wiring, charging systems, sensors, and other electrical components packed into modern heavy-duty trucks aren't simple, and things can go wrong fast. Ignoring the warning signs or delaying inspection can lead to bigger breakdowns down the line. The good news is, most common issues have clear symptoms and patterns. You don’t need to tear your cab apart to get a sense of what might be wrong—you just need to know what to look for and when to step in.

Common Electrical Issues And Symptoms

When something’s off with your truck’s electrical system, it usually shows up in a few obvious ways. The key is knowing what each symptom might point to so you can act before things get worse. Here are some of the most common problems heavy-duty trucks face when it comes to electrical systems:

- Dead batteries – One of the leading culprits, especially if a truck has been sitting unused. Watch for slow engine cranks or no crank at all when turning the key. Dim interior lights or a flickering dome light can be an early flag.

- Faulty alternators – If the battery is always dying, the alternator might not be charging it right. A battery warning light or dimming headlights while driving can tip you off.

- Starter problems – Clicks but no turnover usually means the starter or its wiring is having an issue. Sometimes heat soak can mess with solenoids too.

- Short circuits or blown fuses – If switches or lights stop reacting, you could be dealing with a broken wire, corroded connector, or popped fuse.

- Worn cables or loose terminals – Even something as simple as a top-post battery clamp that’s not tight can throw off the whole system. Keep an eye out for corrosion too—green or white powder around terminals is a sign.

Let’s say your headlights keep going dim when idling, then brighten up when you throttle up. That’s likely your alternator struggling to keep up or worse, starting to fail altogether. These little red flags make a big difference when caught early.

Diagnosing Electrical Problems

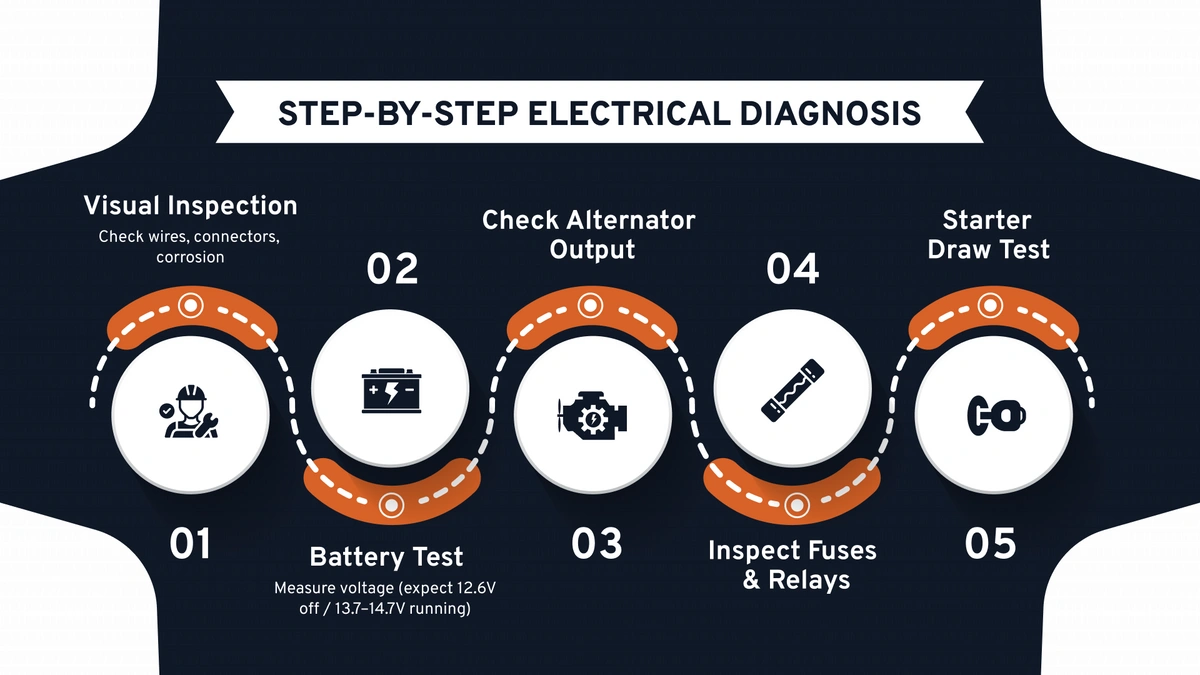

If you’re getting the same symptoms more than once, it’s time to dig a little deeper. Electrical issues can hide in plain sight, so a methodical check goes a long way. Start with the basics, then work your way in:

- Visual inspection – Pop the hood and check wiring harnesses for wear, melting, or broken insulation. Wiggle connectors to spot loose fittings. Look for water damage or corrosion near the battery and fuse panel.

- Battery test – Use a multimeter to check voltage. A fully charged battery should read around 12.6 volts with the engine off. If it drops well below that, it likely needs to be replaced.

- Charging system check – With the engine running, measure battery voltage again. Healthy readings should land between 13.7 and 14.7 volts. Anything lower means the alternator isn’t charging right.

- Inspect fuses and relays – Open the fuse box and pull the ones tied to the system that failed. If one looks burnt or broken, that’s probably your issue. Replace with the matching amperage.

- Starter draw test – If starting is weak or clicking, you’ll want to check how much power the starter's pulling. Too high, and the starter is probably worn. Too low, and there might be resistance in the wiring.

This process helps narrow things down and prevents wasting time on guesswork. And if the issue lies deeper, like an ECM glitch or a fault in the CAN Bus system, that’s where professional diagnostics come in. Trying to fix those yourself isn't just risky, it could end up causing even more damage to the electrical system.

Preventative Maintenance Tips

All the troubleshooting skill in the world won’t matter if the basics aren’t being checked often enough. Electrical gremlins usually creep in when parts get ignored a little too long. The good news is, staying ahead of wear and tear doesn’t take much. Just a consistent routine and some good habits.

The most overlooked problems tend to be the simplest ones: corroded battery terminals, loose grounds, or cracked wires rubbing against the frame. These are small headaches that turn into big downtime if left unchecked. Keeping up with monthly inspections helps catch this stuff early. During scheduled downtime, put the truck through a simple electrical checklist.

Here's your go-to list for electrical system upkeep:

- Check battery connections for tightness and buildup. Clean terminals and apply battery terminal protectant.

- Scan the wire harnesses for signs of heat damage, fraying insulation, or pinched spots.

- Test alternators and starters during routine oil changes to make sure they’re keeping up under load.

- Make sure lights, blinkers, and climate control systems are all working right, which can help catch a bad ground early.

- Replace any cracked plastic fuse covers or broken mounts. Even the box cover being loose can lead to moisture and failures.

- Use dielectric grease on exposed connectors that face road spray or salty conditions to help them live longer.

Using the right parts matters too. Straining a mid-grade alternator on a rig loaded with auxiliary lighting, power take-off systems, or trailers with electric lifts will burn it out fast. Always pick heavy-duty electrical parts that match your truck’s actual workload.

Troubleshooting And Solutions

When something fails, reset and retry isn’t always the answer. Electrical systems require a steady diagnosis process to avoid swapping parts that aren’t bad to begin with. Once you've pinpointed the issue, make sure the fix matches the root cause instead of just patching the symptom.

Let’s say your truck constantly has trouble starting after it’s been running for a while. If it’s not the battery or starter motor, heat soak could be affecting the solenoid. Solve it with better heat shielding or upgrade the components, not just toss in another starter that’ll fail the same way.

Here are a few solution-based checks for the most common electrical quirks:

- If lights flicker under load, check the alternator output and all grounding points.

- For systems that random-reset while driving like radios, HVAC, or displays, test the ignition and dashboard wiring for rubbed-through spots or shared grounds.

- If multiple fuses blow repeatedly, hunt down the short with a fuse buddy or circuit breaker tracer tool versus guessing.

- For trucks outfitted with extra equipment like liftgates or auxiliary power units, verify they aren’t overloading the truck’s stock alternator.

- Windshield leaks near pillars often drip straight onto the fuse box. If you’re chasing mystery shorts, take a peek behind those panels.

A safe bet: if you’ve dug through fuses, wires, and known failure points and still can’t pin it down, the issue is deeper, probably software or sensor-related. That’s the time to get the truck in front of someone with the right scan tools.

Staying Ahead of Downtime

Electrical issues don’t usually give a ton of notice. One minute everything runs fine, and the next, you're troubleshooting a no-start in the middle of a job. Regular checks and the right approach to maintenance are the best way to avoid this.

From weak voltage to faulty grounds, these systems aren’t meant to be ignored. A quick scan of cables, loads, and power draw every few weeks helps keep your truck moving and keeps surprise repairs from wrecking your schedule. Fixing the root cause before it spreads is the difference between a small switch swap and a full-blown wiring repair.

At the end of the day, if your truck’s going to work hard, every part in the electrical system has to pull its weight. Using parts that are fit for the job, keeping eyes on the early warning signs, and following through with the right fix will always cost less than dealing with a breakdown after it's too late.

Keep your truck performing smoothly by focusing on consistent maintenance and using high-quality parts. For all your heavy-duty parts for trucks, rely on the wide selection available at FinditParts Inc. Discover the range of products that can keep your rig road-ready today.