Need help? We're here!

(888) 312-8812 Login SignupThe Ultimate Guide to Semi-Truck Brake Systems: Maintenance, Replacement Parts, and Safety Tips

April 21, 2025

Maintaining the brake system of a semi-truck is not just a regulatory requirement; it's a critical component of road safety. For owner-operators, fleet managers, and mechanics, understanding the intricacies of brake systems ensures not only compliance but also the longevity and optimal performance of the vehicle. This comprehensive guide delves into the components, maintenance practices, replacement parts, and safety tips essential for semi-truck brake systems.

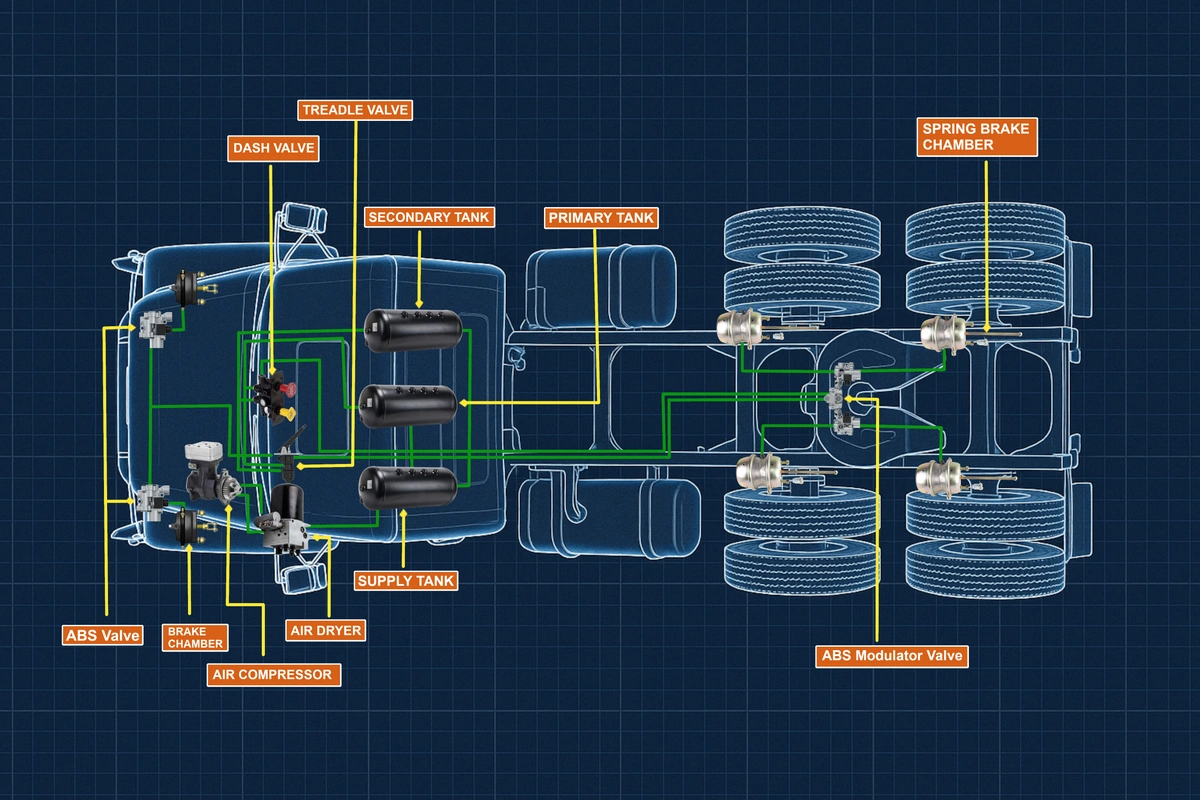

Understanding Semi-Truck Brake Systems

Semi-trucks predominantly utilize air brake systems due to their reliability and efficiency in handling the substantial weight of these vehicles. Unlike hydraulic systems found in smaller vehicles, air brakes use compressed air to actuate the braking mechanism. This design allows for consistent performance and easier coupling with trailers.

Key Components of Air Brake Systems

-

Air Compressor: Generates and supplies compressed air to the system.

-

Reservoirs (Air Tanks): Store the compressed air until needed for braking.

-

Foot Valve (Brake Pedal): Regulates the release of compressed air to the brake chambers

-

Brake Chambers: Convert compressed air into mechanical force to apply the brake

-

Brake Shoes and Drums: Create the friction necessary to slow down or stop the vehicle.

Understanding these components is foundational to grasping how air brake systems operate and the importance of each part in ensuring vehicle safety. 1

Common Types of Brake Systems

Semi-trucks are equipped with different types of brake systems, each with its own set of advantages and considerations.

Drum Brakes

Drum brakes consist of brake shoes that press outward against a rotating drum to create friction. They are known for their durability and cost-effectiveness but may be prone to heat buildup under heavy use.

Disc Brakes

Disc brakes feature brake pads that clamp onto a rotor (disc) to slow the vehicle. They offer superior heat dissipation and consistent performance, especially in demanding conditions, but can be more expensive to maintain.

Comparison of Drum and Disc Brakes

Signs Your Brake System Needs Maintenance or Replacement

Regular inspections can identify issues before they escalate. Be vigilant for the following signs:

-

Reduced Braking Performance: Longer stopping distances or a spongy brake pedal.

-

Unusual Noises: Squealing, grinding, or clicking sounds during braking.

-

Vibrations: Shaking or pulsating sensations when applying brakes.

-

Air Leaks: Hissing sounds indicating leaks in the air brake system.

-

Brake Warning Lights: Dashboard indicators signaling brake system issues

Addressing these symptoms promptly can prevent more severe problems and ensure safety.

Semi-Truck Brake Maintenance Checklist

Implementing a structured maintenance routine is vital for brake system reliability.

Daily Pre-Trip Inspections

-

Check Air Pressure: Ensure the air system builds to the correct pressure before operation.

-

Inspect for Air Leaks: Listen for hissing sounds around brake components.

-

Examine Brake Linings and Hoses: Look for wear, cracks, or damage.

Monthly Maintenance Tasks

-

Test Air Dryer Operation: Ensure moisture is being properly expelled from the system.

-

Check Slack Adjusters: Verify proper adjustment and function.

Quarterly Maintenance Tasks

-

Measure Brake Shoe Thickness: Replace if below the manufacturer's recommended thickness.

-

Inspect Drums and Rotors: Look for scoring, cracks, or excessive wear.

Adhering to this schedule helps maintain optimal brake performance and compliance with safety regulations.

Replacement Parts Guide

When components wear out, choosing the right replacement parts is crucial.

OEM vs. Aftermarket Parts

-

OEM (Original Equipment Manufacturer): Parts made by the vehicle's manufacturer; ensure compatibility and reliability but may be more expensive.

-

Aftermarket: Parts made by third-party manufacturers; can offer cost savings and variety but require careful selection to ensure quality.

Note: Actual lifespan varies based on usage and maintenance practices.

Regular monitoring and timely replacement of these components are essential for maintaining brake efficiency and safety.

Safety Tips for Brake Operation and Maintenance

Ensuring safety involves both proper maintenance and correct operation.

-

Avoid Slamming the Brakes: Sudden braking can cause the system to lock up, increasing the risk of accidents.

-

Use Engine Braking on Descents: Helps prevent brake overheating and fading.

-

Maintain Safe Following Distances: Allows ample time for controlled

Safety Tips for Brake Operation and Maintenance

Keeping your brake system in peak condition is only half the equation—how you operate your brakes on the road also plays a major role in preventing accidents and extending part lifespan. These safety tips apply to every driver, every day:

Top Safety Tips for Semi-Truck Braking

-

Don’t ride the brakes downhill

Use engine braking or Jake brakes to avoid overheating your service brakes on long descents. Excessive heat can lead to brake fade, reducing stopping power when you need it most. -

Watch your air pressure

Most air brake systems operate between 100–125 PSI. If your system drops below 90 PSI, it could trigger a warning and reduce braking ability. Always check pressure gauges before departure. -

Test your brakes before each trip

Perform a brake check during your daily inspection. Listen for air leaks, ensure the air compressor builds pressure properly, and test service and parking brakes before rolling out. (FMCSA Pre-Trip Inspection Guide) -

Keep slack adjusters properly set

Manual slack adjusters need frequent checking and adjusting, while automatic slack adjusters still require inspection to ensure they aren’t sticking or over-traveling. -

Avoid aggressive braking

Heavy, sudden stops increase wear on pads and drums and can lead to jackknifing, especially when under load or in poor road conditions. -

Stay alert to brake fade symptoms

If your brakes feel weak or you're using more pedal pressure than usual, pull over safely and inspect. Continued operation with fading brakes is extremely dangerous.

Brakes Are Your First Line of Defense

Your brake system is one of the most important safety features on your truck—and the one you rely on every single mile. Neglecting maintenance, delaying part replacements, or ignoring warning signs can lead to catastrophic failures, DOT violations, and costly repairs.

Whether you’re managing a fleet or running solo as an owner-operator, investing in quality brake components and routine inspections pays off in performance, compliance, and peace of mind.

Need Brake Parts? FinditParts Has You Covered

Looking for high-quality semi-truck brake parts—fast?

At FinditParts, we stock millions of OEM and aftermarket brake components for every make and model. From slack adjusters to brake pads, air dryers to compressors, we’ve got everything you need to stop safely and drive confidently.

🔧 Browse our full selection of semi-truck brake system parts today—and keep your rig rolling, and stopping, right.