Need help? We're here!

(888) 312-8812 Login SignupTruck Repair 101: How to Troubleshoot Hard Starting Issues

October 15, 2020

Trucks play an integral role in keeping America moving forward. According to the American Trucking Associations, 72.2% of the freight hauled in the U.S. in 2021 was transported by trucks. But just like any other types of vehicles, they are also prone to breakdown, especially when they are not regularly checked and maintained.

Among the most common problems that truckers encounter on the road are hard starting issues. If you’re among them, you’d probably think that it’s the starter motor that is acting up again. However, that is not always the case—sometimes the problem may lie in other electrical system components, such as the batteries, alternator, wiring, or battery switch.

If you can’t get your truck to start and you feel pretty helpless sitting idly by the side of the highway, don’t give up right away. Hard starting issues are often easier to troubleshoot than any other truck problems. So, before you call out for help, you may try these troubleshooting tips to get your truck back on the road fast.

Identify the symptoms

While hard starting issues can be frustrating, identifying these symptoms is highly necessary to determine the best possible troubleshooting steps to take:

· If after turning the key the engine will not crank - The issue is most likely due to an electrical problem. It could be a dead battery, a broken or damaged ignition, or starter engine issues.

· If the engine cranks but won’t fire up - This means the issue is not in the electrical system. For the truck to start, it needs these key ingredients: fuel, air, and compression. So, if the electrical system is all good, then the problem could be related to any of these ingredients.

· If the solenoid does not click and the starter does not crank - Then, you are not getting a spark, which is necessary to ignite the fuel, allowing your truck to start. If you have the technical know-how, you may check for a spark yourself. But if you’re not confident enough, you might as well leave this task to a service mechanic.

Begin with the batteries

Trucks need dependable batteries to perform well. These are responsible mainly for providing the power to crank the starter and start the truck. Once it fails, the truck sits idle, which leads to expensive downtime.

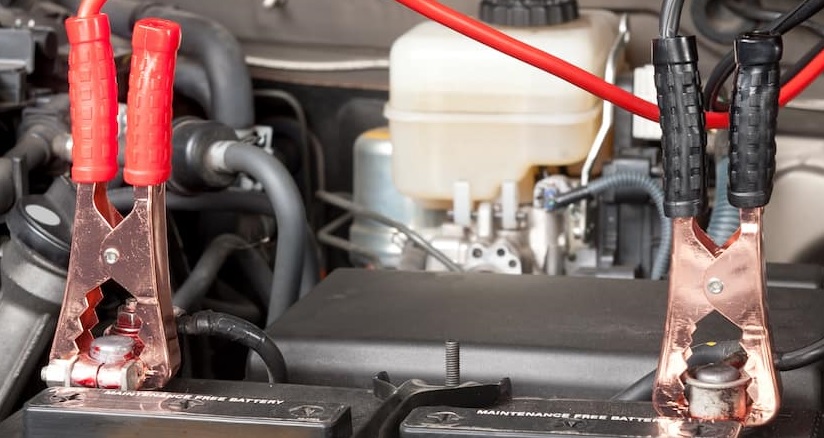

You’ll know if it’s a dead battery that’s likely causing the hard starting issue when you try to turn the key but the engine won’t crank. This is when heavy-duty jumper cables come in handy. These cables can help jump start your truck, so the alternator could recharge the battery as long as the truck is running.

If jump starting did not do the trick, you may try charging the batteries and perform a load test on each battery. If any of the batteries are no longer up to the task, replace them; otherwise, they will shorten the remaining batteries' life and compromise the overall performance of the starting circuit.

Check the cables and sensors

Trucks are equipped with cables that deliver the current from the battery to the starter motor. When any of these cables shake loose, it can lead to hard starting issues. The same is true when a sensor goes out. That is why it’s highly recommended to check these cables and sensors when performing preventive maintenance.

If you see any of these cable and sensor issues upon inspection, you may try reconnecting or restoring the problem part. You may also check for undersized cables or poor-quality or corroded terminals. Take note that over half a volt in voltage drop may lead to potential starting problems, so you’d better replace them with the right cable size.

Look into the alternator

The alternator is a critical electrical component used in trucks to generate electricity to recharge the battery. This, then, helps provide power to operate the starter, ignition, and all the electronic accessories found in your truck. If you have trouble starting your truck but the battery is all good, then you may look into the alternator.

Batteries that do not get charged fully could mean that your truck’s alternator capacity may no longer be up to the needs of your big rig. Most fleet owners now go for brushless alternators because they are made to last for over a million kilometers compared to standard brushed alternator, which is only good for 100,000 to 150,000 kilometers, and a longer brush alternator that lasts only up to 300,000 kilometers.

However, before you swap out your stock alternator to a high output alternator, be sure to check your truck’s wiring size. Some trucks have undersized cables, and their cable gauge size may not be a good match to the alternator’s total amperage.

Do a fuel line check

A cranking engine but won’t start may be a fuel-related hard starting problem. This is especially true during cold weather. A frozen fuel line may lead you to think that the tank still has enough fuel even if it is already empty. So that’s probably the reason why your truck won’t start—the mis-calibrated fuel gauge failed to inform you that your truck is actually out of gas.

Another part to check is the fuel filter. How long since you last replaced it? When the fuel filter gets clogged, the right amount of fuel won’t reach the engine, leading to a hard start. So, replace it if necessary.

Replace the starter motor

If the starter motor is indeed the culprit, then it’s high time you get a replacement starter motor. The starter is responsible for starting up the combustion engine, so be sure not to skimp on this part. If your budget doesn’t allow for a genuine starter, you can always go for an OEM starter or an aftermarket starter. Both options are made to the highest quality standards, so they’re guaranteed to fit and work just like the genuine unit.

The total cost of unexpected downtime due to hard starting issues can vary greatly. And this cost may include repair or replacement of parts, towing, and other expenses incurred simply because the load delivery is late. So, make sure to check these critical starting components—starter motor, battery, alternator, cables, sensors, fuel line, and fuel filter—regularly to avoid costly downtime and other inconveniences.

When you need to fix hard starting issues look no further than Find it at FinditParts. With our vast number of sources and enhanced visibility into the inventory of distributors and manufacturers of OEM and aftermarket brands, you’re only a few clicks away from the parts you need. Need help? Our focus on service and support provides you with a repository of valuable information, customer facing technology including advanced cross reference capabilities, and technical specialists who assist in identifying and finding parts.

Related Reading:

Cores and Remanufactured Parts

https://www.finditparts.com/blog/cores-and-remanufactured-parts

Commercial Vehicle Battery Testing & Maintenance: A Beginner’s Guide

https://www.finditparts.com/blog/commercial-vehicle-battery-testing-maintenance-a-beginners-guide

The Growing Trend to Predictive Maintenance

https://www.finditparts.com/blog/the-growing-trend-to-predictive-maintenance