Need help? We're here!

(888) 312-8812 Login SignupAlternative Parts Sourcing

March 28, 2022

Raw material and parts shortages have been plaguing the trucking industry for months. Trying to get items like NOx sensors, EGR coolers, exhaust gaskets, water pumps, and even brake parts can seem like a quest for the holy grail.

Not being able to get needed parts is very problematic for fleets, as downtime has been pegged at more than $1,000 a day, and that does not factor in the hit the fleet takes to its relationships with its customers who are not getting the goods they need. As many fleets move outside traditional channels to find parts, understanding where and how to source replacements efficiently has become critical for keeping vehicles on the road.

While there is no one sure-fire go-to source for parts these days, here are some options for alternative sources for parts.

1. Expand your geography: While your local distributor has always been your preferred parts supplier, looking outside your immediate area can yield the part you seek. Consider the entire United States your backyard when it comes to sourcing parts. Of course, there will be shipping costs, but that beats having a truck sit for days or weeks on end waiting for a part from your local distributor.

Fleet managers can also benefit from using data-driven analyses to lower parts costs and increase productivity when expanding their sourcing network. By identifying trends in availability and pricing, fleets can make smarter purchasing decisions—even when working with distant suppliers.

2. Consider all makes parts: If you’ve always purchased branded parts, now might be the time to consider private-label all makes parts. These parts are typically purchased by the second, third, or subsequent truck owners because of their price point, but can be an option when the branded part can’t be found. Many of the truck OEMs offer all makes of parts backed by warranties.

3. Turn to the internet: Online parts sellers are another option, as they tend to have a wide and deep inventory of parts. Choose ones that specialize in heavy-duty truck parts and that have cross references and offline support people who can answer your technical questions. Knowing what to look for from an online parts seller can make a big difference—especially in assessing product authenticity, warranty coverage, and customer support.

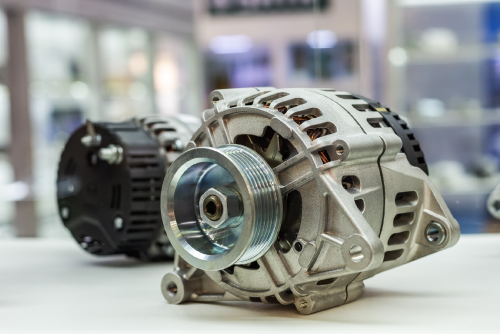

4. Look into reman parts: Remanufacturing takes a product and tears it down into individual components, which are inspected to determine if they can be reused. The part is then put back together and returned to the same as new or better condition. When choosing a remanufactured part, make sure the remanufacturer follows OEM policies, specifications, and replacement criteria.

The rise of e-commerce’s role in parts procurement has made it even easier to find and compare remanufactured parts. Online platforms now allow fleets to review warranty terms, inspect quality certifications, and order verified components faster than ever before.

5. Add rebuilt parts: These parts have been cleaned and inspected. Components that are worn or broken are identified, and only those parts are replaced. These parts usually come with limited warranties.

More fleets also find value in building long-term relationships with trusted distributors and digital vendors. As online parts sellers become reliable partners for fleets, they provide broader inventories, responsive customer support, and access to hard-to-find parts when supply chains tighten.

6. Think about used parts: Usually, these parts have been salvaged from vehicles that may have been involved in a collision or are at the end of their useful life. These parts can be a stopgap to get your truck back on the road until you can get a new replacement part.

No one knows for sure when the supply chain disruption will end, and truck parts will be plentiful again. Until things return to normal, try some of the above options to get trucks back on the road, making deliveries.