Need help? We're here!

(888) 312-8812 Login SignupTips for Safe Load Distribution and Security

September 04, 2025

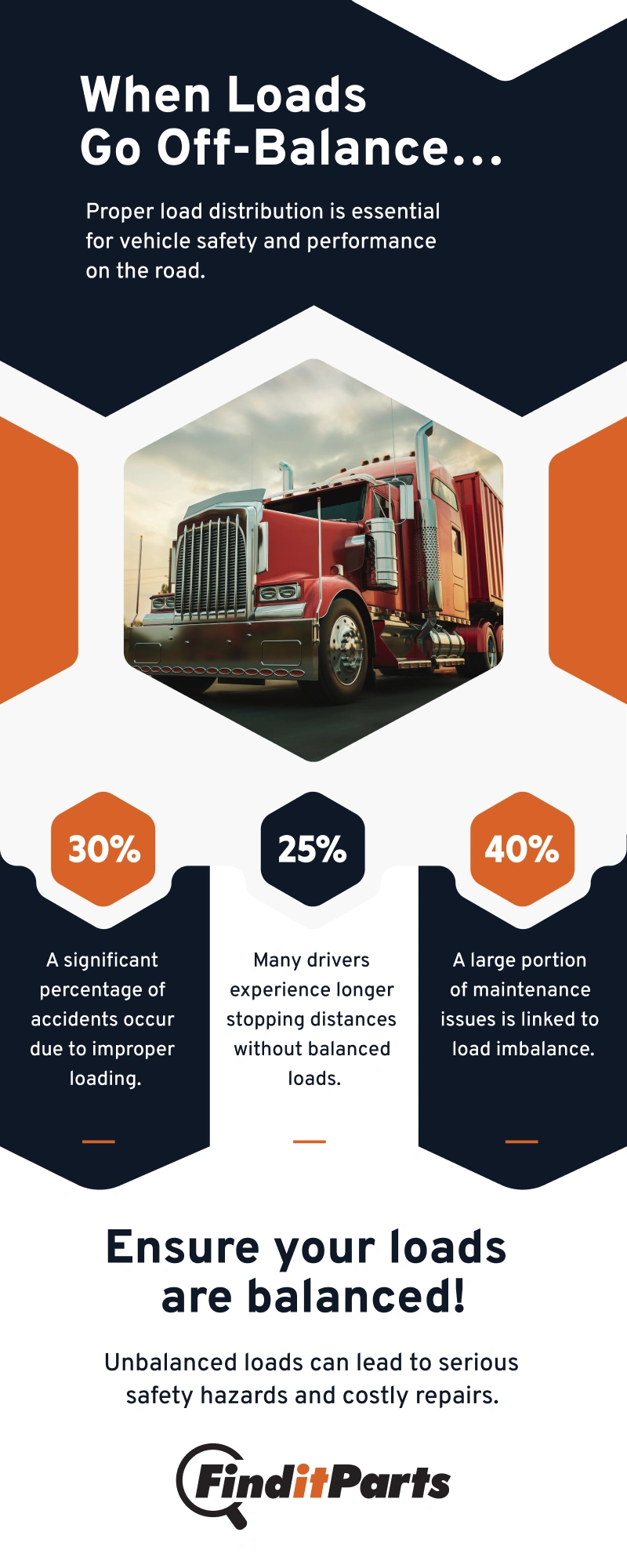

When you’re hauling cargo down the highway, the last thing you want to think about is whether that load is going to shift mid-turn or throw off your rig’s balance. Poor load distribution or a loose strap can turn a routine trip into a serious problem in a matter of seconds. It’s not just about keeping the cargo intact. It’s about keeping your truck in control, your tires from wearing out too fast, and everyone on the road safe.

One example that hits home is when a flatbed load wasn’t properly secured and shifted hard during a lane change. The result? A total blowout on one side, a bent frame, and days lost dealing with citations and repairs. Such incidents occur more frequently than you might think, and the cause often stems from neglecting the fundamentals of load handling or using subpar components. You don’t need to overthink it, but you do need to do it right. That starts with making sure your load is balanced.

Importance Of Proper Load Distribution

Getting the load weight spread out the right way isn’t just some nice-to-have detail. It affects how your truck handles, steers, and stops. When the weight leans too far to one end or side, it puts everything out of whack. You may notice that the steering becomes harder, your truck pulls slightly, or you have trouble braking evenly. That’s the truck’s way of telling you it's overloaded or unbalanced somewhere, and following proven ways to prevent truck accidents is the best way to correct these issues before they lead to a crisis.

Here’s what can happen if your distribution is off:

- Suspension parts wear faster due to uneven stress

- Tires heat up and wear unevenly, leading to blowouts

- Brakes grind harder and take longer to stop

- The risk of tipping increases, especially during turns or quick maneuvers

It doesn’t take an expert to spot the signs. If your truck seems like it’s working overtime, especially during turns or stops, chances are something’s not lining up between the load and the axles. Carrying too much weight on a single axle can also result in failing a weigh-in at a station, which opens the door to fines and forced unloads.

Overloading is another thing to look out for. It’s tempting to pack as much as you can to make fewer trips, but that move can bite you. Axle weight limits exist for a reason. Exceeding them doesn’t just cause mechanical problems. It can also land you in legal trouble. Learning how to load in a way that keeps weight under legal limits without sacrificing stability is what separates a good hauler from a great one.

The right planning goes a long way. Sketch out where things will sit, factor in the center of gravity, and try to balance the load front to rear and side to side. Don’t overthink it, just be smart about it.

Techniques For Effective Load Securing

Once your load is balanced, the next step is to ensure it remains in place. Straps, chains, bars, and tarps are not all used the same way. Some jobs require heavy-duty chains, while others necessitate adjustable ratchet straps or load bars that span across the trailer. The key is to use tools that match the cargo’s weight and shape, and to double-check all anchor points. Staying updated on the latest advancements in truck components can help you find more durable, high-efficiency tie-downs that make securement easier and more reliable.

Here are a few tried-and-true methods:

- Use ratchet straps for tight, adjustable holds on general freight

- Lock down heavy equipment with transport chains and tensioners

- Apply edge protectors to avoid cutting into cargo or straps

- Use E-track systems with logistics straps for interior trailer hauls

- Cover loads with tarps and secure the corners to block wind movement

Don’t forget, it’s not just about using the right tools. You must inspect them before every use. Frayed straps, rusted chains, or stretched-out bars won’t hold under stress. Quality matters too. Obtaining reliable, heavy-duty parts for trucks can mean the difference between a safe haul and a roadside disaster.

Always give one final pull or shake before rolling out the dough. If it moves, fix it. If it holds tight, you're good to go. Simple as that.

Regular Inspections And Maintenance

Every strap, chain, and anchor point you use takes a beating over time. The road, the weather, and long hours at full tension can wear them down faster than you might expect. That’s why regular inspections shouldn’t be something you skip. Before every trip, take ten minutes to walk around the load and check each piece of securing equipment as part of a long-distance pre-trip inspection.

The sooner you spot issues, the easier they are to fix. A frayed strap might hold up during a quick haul across town, but that same strap could snap on a long-distance load. The trick is to replace parts before they become a problem, not after they disrupt your day.

Establish a routine that incorporates both visual inspections and hands-on assessments. Give tensioners a few cranks to see if they still hold tight. Check that load locks click into place and don't wiggle loose. Make sure edge protectors aren't cracked or brittle. Consistent maintenance of your gear is one of the most effective habits to keep your truck roadworthy and minimize the risk of part failure.

For longer hauls, do mid-trip checks at fuel stops or rest areas:

- Recheck the strap and chain tension

- Tighten or re-secure loose tarps and wraps

- Scan tires for any bulging caused by shifting weight

- Re-center anything that looks like it slipped out of position

Maintenance also means proper storage. Keep your straps and chains dry between runs. Don’t toss them under dripping tarps or leave them baking in the sun for days. Taking care of your gear helps it last longer and perform better. Invest in replacements as soon as you notice signs of failure. Thinking, “It’ll make it one more load,” is precisely how minor problems grow into bigger ones. That gamble’s not worth it.

Staying Compliant With Legal Load Limits And Securement Rules

There’s no bigger headache than getting flagged during a DOT stop because of a messed-up load. Laws can vary from state to state, but the basics stay the same. You must keep the total weight under axle limits and secure everything so that nothing shifts or falls off during transport. It doesn’t matter if you’re hauling lumber, pipe, machinery, or pallets of boxed goods. The rules apply across the board.

If your load isn’t properly secured, you’re looking at more than just warnings. Violations can trigger on-the-spot fines, force you to stop hauling until the issue is fixed, or even put points on your driving record. Recurring problems can render a truck entirely out of service. If you must adjust your load while on the road, always pull into a safe area and mind standard truck stop dos and don’ts to avoid interfering with other drivers' workflows.

Make it a habit to stay current with changes to FMCSA cargo securement regulations. These rules cover everything from the minimum number of tie-downs to how cargo should be braced against side-to-side and front-to-back movement. They also specify how tie-downs should be rated, used, and positioned based on the type of cargo.

Simple ways to stay compliant:

- Use enough tie-downs based on your cargo length and weight

- Make sure your tie-downs are rated to your cargo’s load weight

- Prevent load shifts with blocking, bracing, friction mats, or all three

- Secure any tools, spare tires, or parts that could move around in transit

Being aware of the rules puts you in control. If something changes, it’s better to hear it from a regulation sheet than during a roadside inspection. A little bit of prep time can save you from a lot of stress.

How FinditParts Helps You Keep Cargo Locked Down

Truckers and fleet managers who take cargo safety seriously know that the details matter. A well-loaded trailer can still go sideways if you’re using sketchy hardware or hold-down systems past their prime. Quality matters. Parts built to handle stress, heat, and rough weather make your job easier and your haul safer.

Whether you’re working with box trailers, reefers, flatbeds, or step decks, the right parts help you stay ahead of trouble.

There’s no substitute for peace of mind when your equipment is road-ready. You won’t need to second-guess that one strap or worry whether your load is holding. You’ll know.

Plan ahead. Inspect gear regularly. Swap out weak parts early. And count on truck parts that are made to do the job right. Driving safely starts with loading smart, and sticking with gear that’s built to do the job keeps your wheels rolling strong. Every time.

Ensure your cargo stays secure with reliable components built to handle the job. Browse our hand-picked selection of heavy-duty parts for trucks to keep things running smoothly from the loading dock to the delivery stop. FinditParts Inc. has what you need to haul with confidence and peace of mind.