Need help? We're here!

(888) 312-8812 Login SignupHow Technology Is Changing the Trucking Industry

September 04, 2025

The trucking industry has been going through major shifts, and a big part of that change comes from new technology. Whether it’s safety systems, smart sensors, or data tracking, these updates are helping drivers and fleet managers work smarter. As trucks get more advanced, so do the ways people manage, drive, and maintain them. Advances in heavy-duty truck components are playing a huge role in keeping trucks reliable and efficient, from engine parts to braking systems.

For those working closely with heavy-duty trucks, the tech upgrades aren’t just for show. They're changing how jobs get done on the road and in the garage. Better safety, stronger tracking, and quicker problem-solving all mean more uptime, fewer breakdowns, and smoother operations overall. Let’s look at a few of the biggest changes shaping how trucking looks today.

Advanced Driver Assistance Systems (ADAS)

Trucks these days come packed with features designed to help drivers avoid accidents and handle their rigs more confidently. These features fall under Advanced Driver Assistance Systems, or ADAS. From the dashboard to the brake system, these built-in tools are lowering risks and giving drivers more support during long hours on highways or back roads.

Some of the most common ADAS features include:

- Lane-keeping assist: A system that gently steers the truck back in its lane if it begins to drift

- Adaptive cruise control: Adjusts speed automatically based on traffic to maintain a safe distance from other vehicles

- Emergency braking: Detects slower traffic or stopped vehicles and applies the brakes if the driver doesn’t react in time

- Blind-spot monitoring: Alerts drivers when there’s a vehicle in a spot they can’t see in their mirrors

Each of these tools works quietly in the background, stepping in only when needed. The point isn't to take full control of the truck but to back up the driver when something unexpected happens. Using best practices to prevent truck accidents can be significantly supported by these modern ADAS features.

Think about a driver hauling a heavy load through a mountain pass. Lane-keeping assist can help the truck hold its line on tight turns, especially if the driver starts to drift after a long shift. Knowing the system is there doesn't replace careful driving, but it adds an extra layer of safety that can make a real difference when it matters.

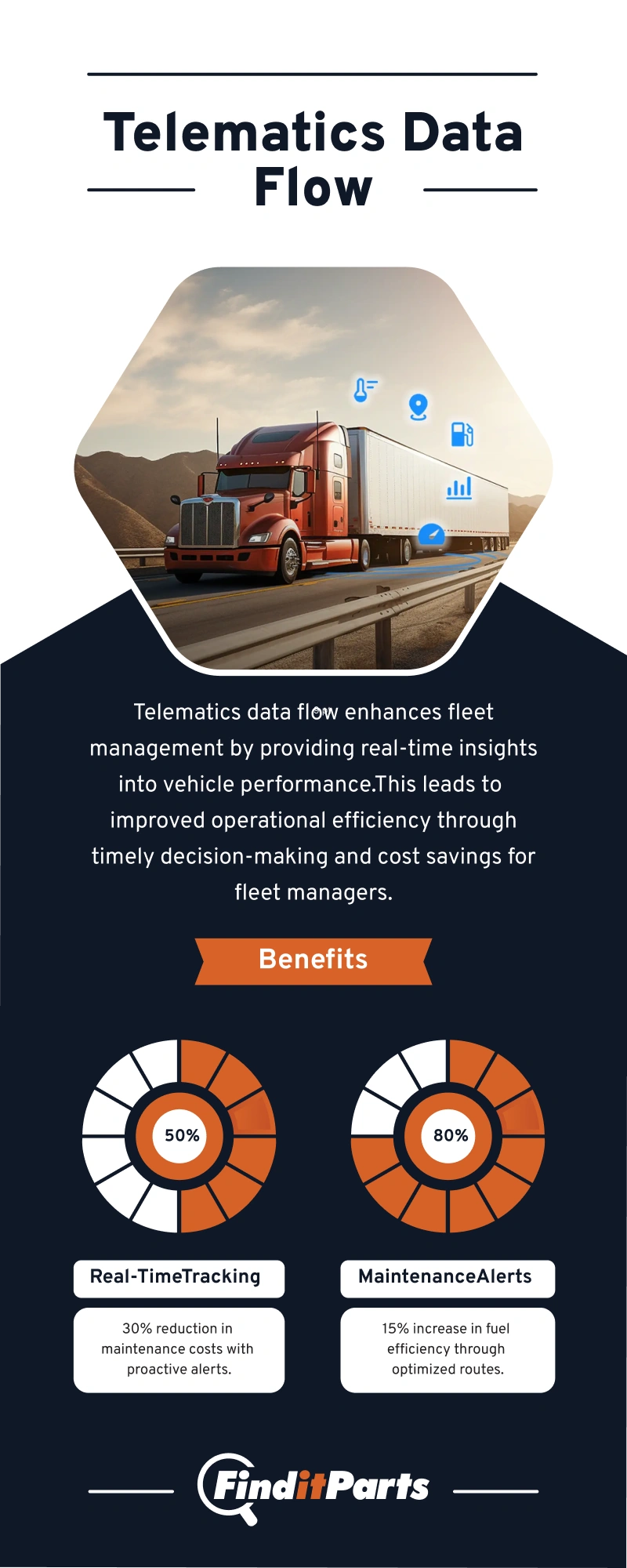

Telematics and Fleet Management Software

Telematics might sound like a fancy term, but it's basically about collecting and using information from a vehicle to make better decisions. When paired with fleet management software, telematics turns raw data into something useful.

At its core, telematics tracks:

- Location and route history

- Driving behavior, like speed and braking

- Fuel use and idle time

- Maintenance needs and fault codes

All of this gets sent back to fleet managers in real time. From there, it’s easier to spot waste, plan better routes, and keep tabs on driver performance. You might notice a truck idling more than usual in one region or that another isn't taking the most efficient path to its destination. With the data, adjustments can be made that lower costs and improve schedules.

Fleet management software pulls all this information into one place. It gives teams the power to move fast when maintenance is due or when a part shows signs of failure. This kind of control makes it easier to keep your truck roadworthy consistently.

For people responsible for keeping trucks on the road, this technology is like having an extra set of eyes watching over every vehicle. And when it leads to less downtime, happier customers, and fewer surprises, it’s hard to ignore the upside

.

Electric and Autonomous Trucks

The push toward electric vehicles isn't just for cars. Trucks are joining the shift too. Electric trucks are gaining traction and bringing several benefits. Think reduced emissions, lower fuel expenses, and fewer moving parts to maintain. These trucks run quieter, cleaner, and often at a lower overall cost over time.

- Electric trucks rely on large battery packs instead of traditional diesel engines. Because they have fewer moving parts, they tend to need less maintenance. Fleets aiming to be more sustainable can adopt tips to make truck eco-friendly to complement their electric vehicle investments.

- Right behind electric trucks come autonomous ones. These self-driving vehicles are still in development, but they’re making steady progress.

- They use cameras, sensors, and real-time data to navigate roads and traffic conditions. While they aren’t replacing drivers just yet, they’re being built to support them by handling some of the more repetitive or tiring parts of long-haul trips.

This could mean safer highways, fewer accidents caused by fatigue, and more flexibility in transport logistics. Keeping up with these changes now helps fleet operators prepare for the new normal down the road. These improvements also align with new environmental rules for heavy-duty trucks, which increasingly emphasize lower emissions and cleaner operations.

Predictive Maintenance and IoT Integration

Keeping heavy-duty trucks in good shape has always been important. Thanks to IoT sensors and predictive maintenance tools, it’s becoming easier to get ahead of mechanical issues before they cause a breakdown.

Internet of Things (IoT) sensors monitor things like engine performance, brake wear, and fluid levels in real time. The data goes straight to fleet managers who can act fast if something looks off. If a sensor picks up something unusual—like engine vibration or high temperature—it can trigger an alert to inspect that component before it fails.

This level of insight helps plan maintenance around actual vehicle conditions instead of guesswork. Trucks spend less time in the shop and more time doing what they’re made to do: move freight. Predictive maintenance also means you can order the latest heavy-duty truck components promptly when wear appears, not after a breakdown forces the issue.

By fixing problems early, fleets can save time, avoid expensive repairs, and keep operations running smoothly. The fewer surprises on the road, the better it is for drivers, customers, and the business as a whole.

What’s Next for Trucking Technology

Technology never stands still, and neither does the trucking business. Staying updated keeps you competitive. As these systems become more common and effective, the advantage will go to those who are ready for them.

Fleet managers who study these tools and know how to use them are already getting ahead. With a mix of safety systems, smarter data use, and electric options, trucking is becoming more efficient and reliable than ever.

Change can be hard, but the rewards for paying attention and adapting early are worth it. From better safety records to fewer repair surprises, the benefits touch every part of the operation. Little by little, these changes are reshaping how trucks move across the country. Those who stay curious and ready to learn will be the ones driving that future forward.

As the trucking industry moves forward with new technological advancements, it's important to equip your fleet with the right resources. Explore our selection of heavy-duty parts for trucks at FinditParts Inc. to keep your vehicles running at their best. Embrace the future with confidence, knowing you've got the right parts to support your operations effectively.