Need help? We're here!

(888) 312-8812 Login SignupHow to Diagnose and Replace a Faulty Truck Starter Motor

July 18, 2025

When your truck refuses to start, a faulty starter motor is often the culprit. Understanding how to diagnose and replace this essential component can save you time, money, and prevent unexpected downtime. This guide will walk you through identifying starter issues and the steps to replace it, ensuring your truck gets back on the road efficiently.

Signs of a Failing Truck Starter Motor

Recognizing the early symptoms of a failing starter can prevent more significant issues down the line

-

Clicking Noise: A rapid clicking sound when turning the key often indicates the starter solenoid is engaging, but the motor isn't turning.

-

Slow Cranking: The engine turns over sluggishly, suggesting the starter is struggling to spin the engine.

-

No Response: Check fuses and the remote solenoid (on the firewall or in the battery box) and then the starter.

-

Smoke or Burning Smell: Overheating due to continuous attempts to start can cause smoke, indicating electrical issues within the starter.

-

Oil-Soaked Starter: Oil leaks can contaminate the starter, leading to malfunction.

Diagnosing Starter Motor Issues

Before replacing the starter, it's crucial to confirm it's the source of the problem:

-

Check the Battery: Ensure the battery is fully charged and the terminals are clean and tight. A weak battery can mimic starter issues.

-

Inspect Electrical Connections: Examine the wiring between the battery, starter, and ignition switch for corrosion or loose connections.

-

Test the Starter Solenoid: Listen for a clicking sound when turning the key. Absence of this sound may indicate a faulty solenoid.

-

Bench Test the Starter: Remove the starter and connect it directly to a battery to see if it operates correctly.

Tools and Parts Needed for Replacement

Gather the necessary tools and parts before starting the replacement process:

Step-by-Step Guide to Replacing the Starter Motor

-

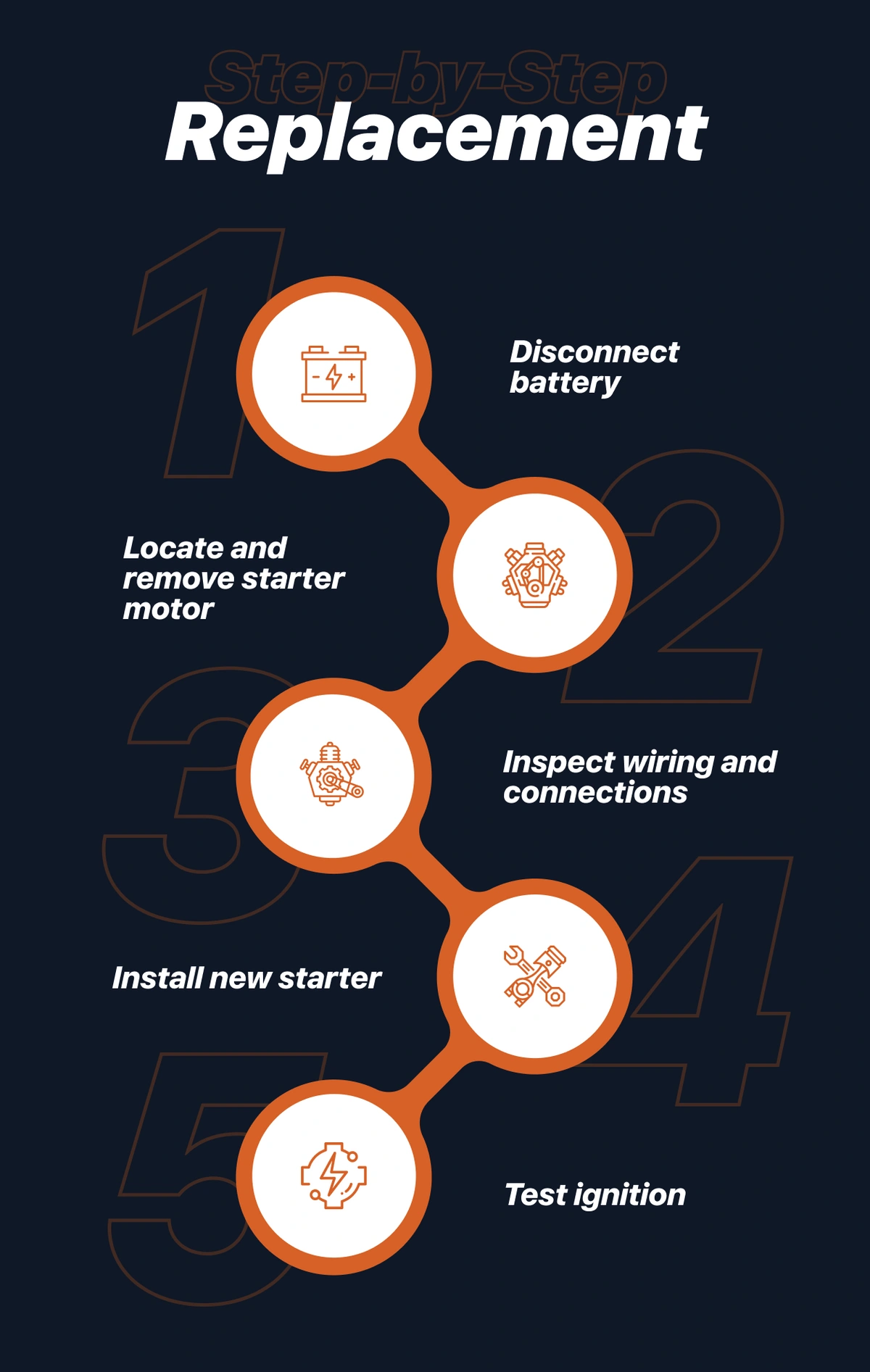

Safety First: Park the truck on a flat surface, engage the parking brake, and disconnect the negative battery terminal to prevent electrical shocks. Back feed or shorting it can cause ECM issues as well as accidentally engage the starter

-

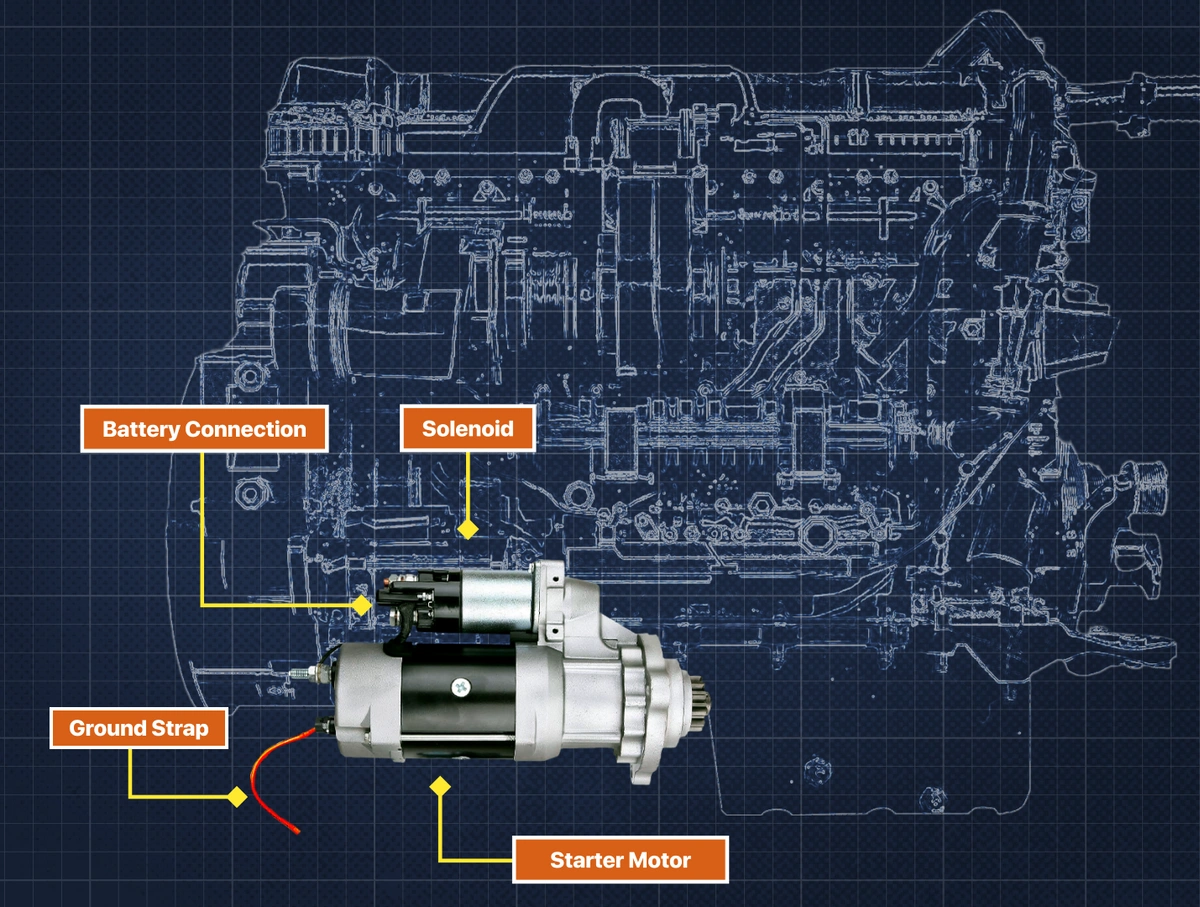

Locate the Starter: Typically found near the bottom of the engine, where it connects to the transmission.

-

Remove the Old Starter:

-

Disconnect the wiring connected to the starter.

-

Unbolt the starter from the engine block.

-

Carefully remove the starter from its housing.

-

-

Install the New Starter:

-

Position the new starter into place.

-

Bolt it securely to the engine block.

-

Reconnect the wiring to the starter terminals.

-

-

Reconnect the Battery: Attach the negative battery terminal

-

Test the Installation: Start the engine to ensure the new starter operates correctly.

Tips for a Successful Replacement

-

Double-Check Connections: Ensure all electrical connections are secure and free from corrosion.

-

Use the Correct Torque: Tighten bolts to the manufacturer's specified torque to avoid damage.

-

Inspect Related Components: While replacing the starter, check the condition of the flywheel and other nearby parts for wear or damage.

When to Seek Professional Help

If you're uncomfortable performing the replacement yourself or if the problem persists after installation, consult a professional mechanic. Some issues may stem from other components like the ignition switch or neutral safety switch.

Conclusion

Diagnosing and replacing a faulty truck starter motor is a manageable task with the right tools and knowledge. Regular maintenance and prompt attention to starting issues can keep your truck running smoothly and prevent costly repairs down the line.

For high-quality starter motors and related components, visit FinditParts. Our extensive inventory ensures you'll find the right part for your truck's make and model.