No B.S Guide to Brake Safety Week for Truckers

Whether you’re a veteran driver who wants a quick brush-up or a rookie looking to learn the ropes, let this be your go-to guide for Brake Safety Week. We understand there’s nothing quite as important as the brakes, and recognize the responsibility to maintain and regularly check the brake systems. This annual event, led by the Commercial Vehicle Safety Alliance (CVSA), focuses on preventing brake-related accidents through rigorous inspections. We’ve designed this guide to be your comprehensive resource, offering practical advice, maintenance tips, and expert insights to ensure your vehicle remains safe and compliant.

Understanding Brake Safety Week

Chances are you probably have already heard about Brake Safety Week and probably know someone who might have gotten a violation. These can be costly, costing hundreds of dollars. Nobody wants that plus it's best to operate your truck safely anyway. For those who need a refresher, Brake Safety Week is part of the Operation Airbrake Program by the CVSA, in partnership with the Federal Motor Carrier Safety Administration (FMCSA) and the Canadian Council of Motor Transport Administrators. Inspectors across the United States, Canada, and Mexico will conduct thorough examinations of commercial vehicles, focusing on their brake systems. Any vehicle found with out-of-service (OOS) violations will be sidelined until those issues are fixed. So we’ve created this article to help ensure you don’t get one of these violations.

What Inspectors Look For During Brake Safety Week

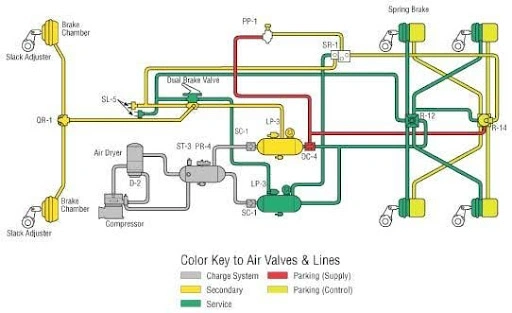

During inspections, specific components of the brake system are looked at, including:

-

Brake Lines and Hoses: Inspectors check for any damages, leaks, or signs of wear that could compromise the brake system’s integrity.

-

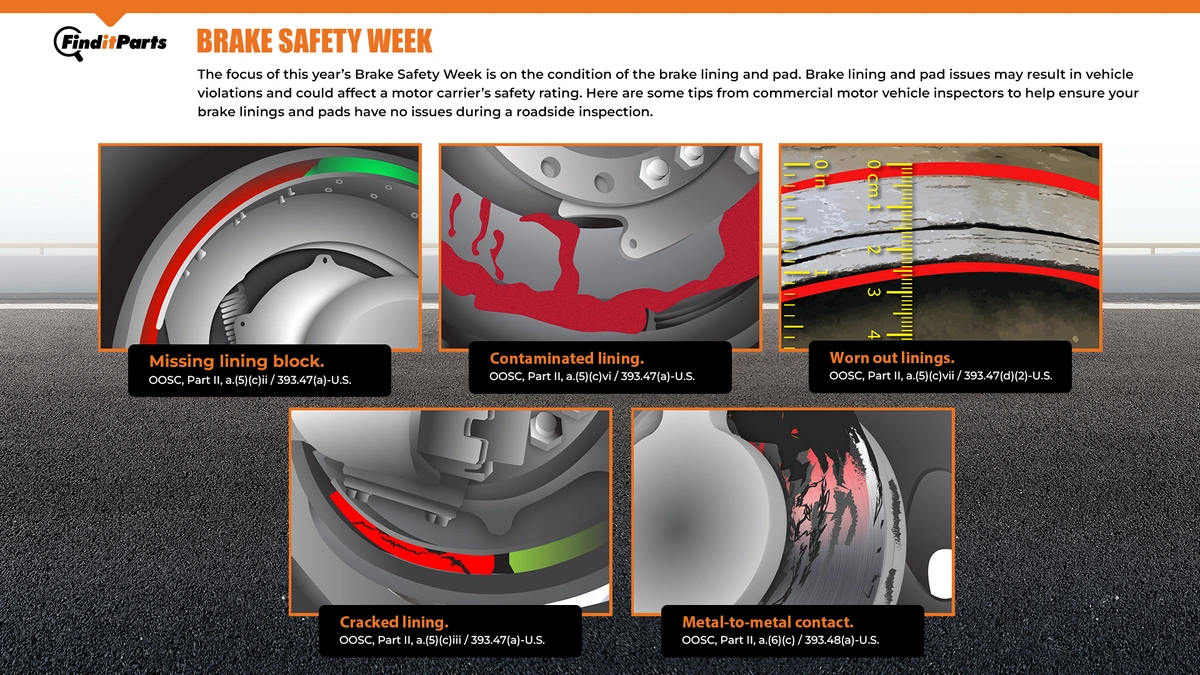

Brake Pads and Linings: Special attention is given to the thickness and condition of brake pads and linings, ensuring they meet safety standards.

-

Additional Components: This includes a check on drums, rotors, and the anti-lock braking system (ABS) indicators, looking for any malfunction or wear that could affect braking performance.

At the end of the day, CVSA is trying to keep us all safe, and they have some great data to help us in the trucking industry understand the most problematic areas with the braking system. It might sound obvious but brake lining and pad condition continue to be the main area of focus.

Expert Insights on Brake Safety

We interviewed one of our very own parts expert, Jim Phair, with 25 years of experience in the industry about the important aspects of brake safety:

FinditParts: What were some best practices for maintaining brake systems on heavy-duty trucks?

Jim Phair: Basically, you want to make sure you’re inspecting all the components and brake systems after every road trip. You want to make sure that your air tanks are properly drained, and that there is no contamination or moisture in them.

FinditParts: How frequently should you inspect your semi truck’s brake systems?

Jim Phair: Making regular inspections of S Cams, slack adjusters, and brake shoes a routine is best to make sure everything is always looking good. But what’s important is to every once in a while do a full inspection. Pull the wheel off the truck and make sure you get a good look at the breaks and the drums and take a closer look to make sure they're not worn out.

FinditParts: What are the key components of a heavy-duty truck brake system that require regular maintenance?

Jim Phair: That would be the brake shoes. You want to make sure that they're within specs and they're not worn out. As I mentioned before, the slack adjusters need to be adjusted properly. Other related foundation parts such as S cams and bushings; make sure they’re not worn out, there's no slot in them, and that they're greased and lubricated properly so they don't wear out. It's all part of the regular maintenance that you perform on and after every road trip.

Practical Steps for Compliance and Safety

-

Documentation Readiness: Ensure all your vehicle’s maintenance records, including brake system repairs and checks, are organized and readily available. You don't want to be fumbling around trying to find necessary paperwork when inspectors ask.

-

Pre-Trip Inspections: Make these inspections a non-negotiable part of your daily routine. Use the CVSA’s checklist as a guide to thoroughly examine your vehicle’s brake system, including air pressure, hose conditions, and pad thickness.

-

Engage with Professionals: Establish a relationship with a reputable maintenance provider. Regular professional inspections and maintenance can catch issues that may be overlooked during routine checks.

-

Keep eyes out for:

- Loose or missing parts

- Air or hydraulic fluid leaks

- Anti-lock braking system (ABS) indicator lights

- Other faulty brake-system components

Before You Hit the Road: A Checklist

To help you prepare for Brake Safety Week—and every week thereafter—here’s CVSA’s checklist to ensure your brakes are in top condition:

-

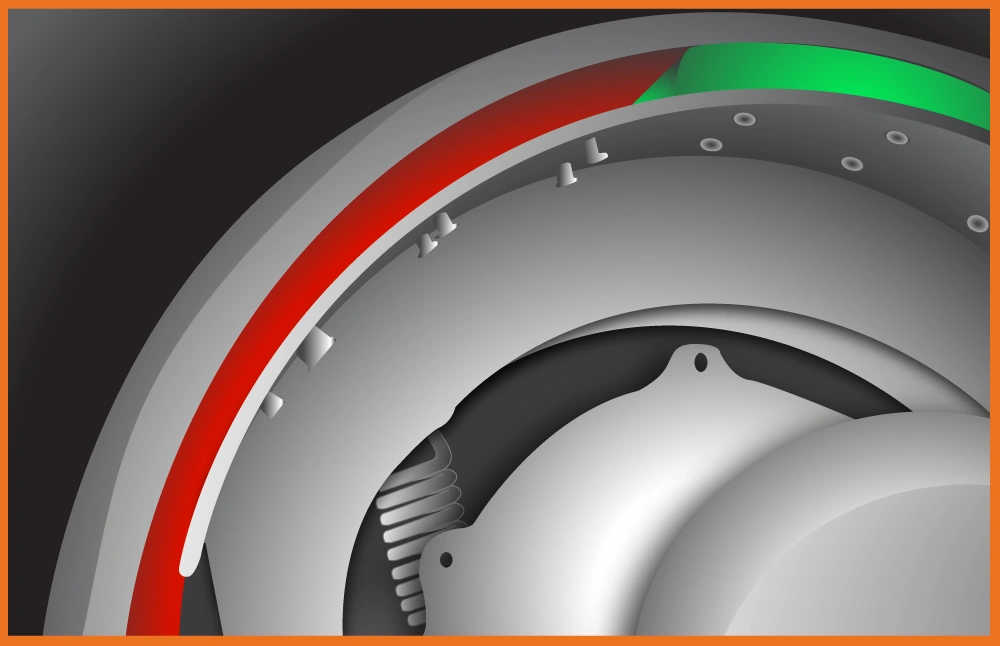

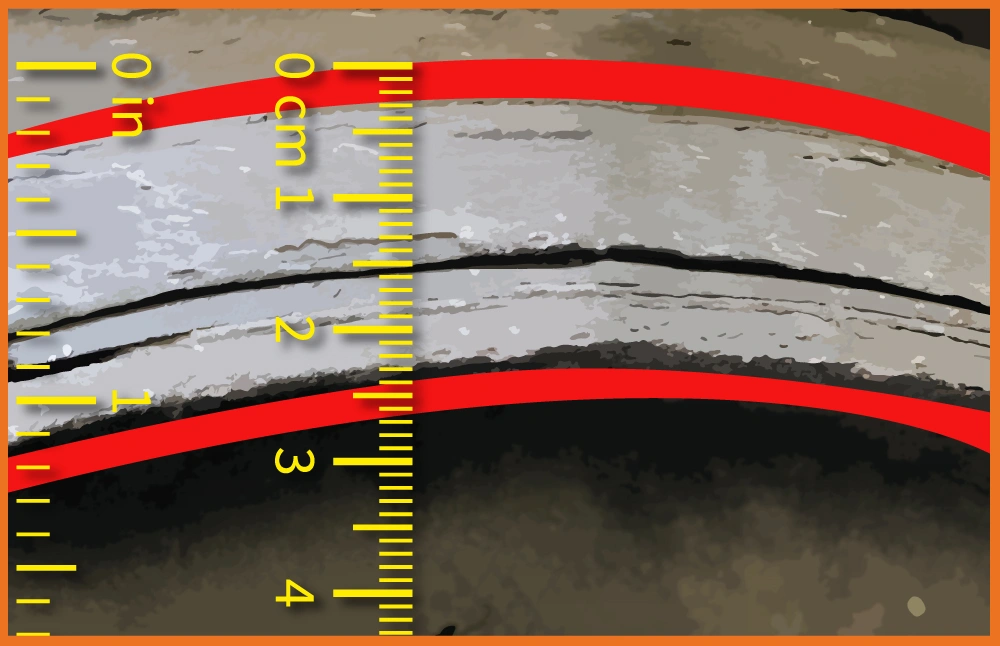

Inspect visible portions of the brake lining and pads as part of your pre- and post-trip inspections.

-

Look for signs of missing lining, such as grooves in the drum from rivet contact.

-

Look at the shoe-to-drum clearance and ensure there is adequate lining on the shoe.

-

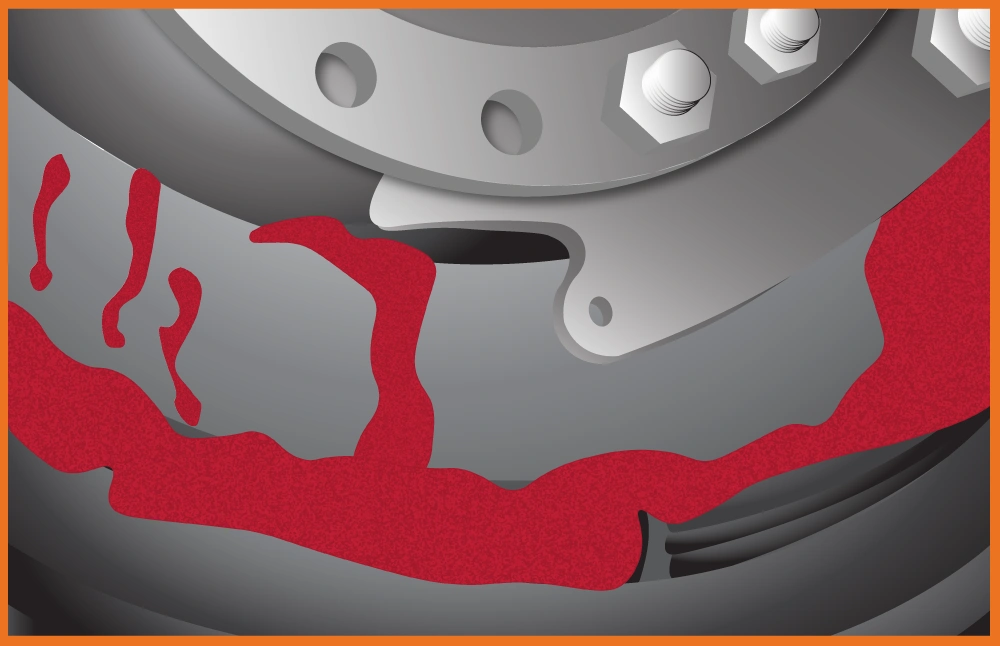

Look for any signs of leaks from the hub or other components that may be contaminating the lining/pad surface.

-

Ensure there are no missing lining blocks.

-

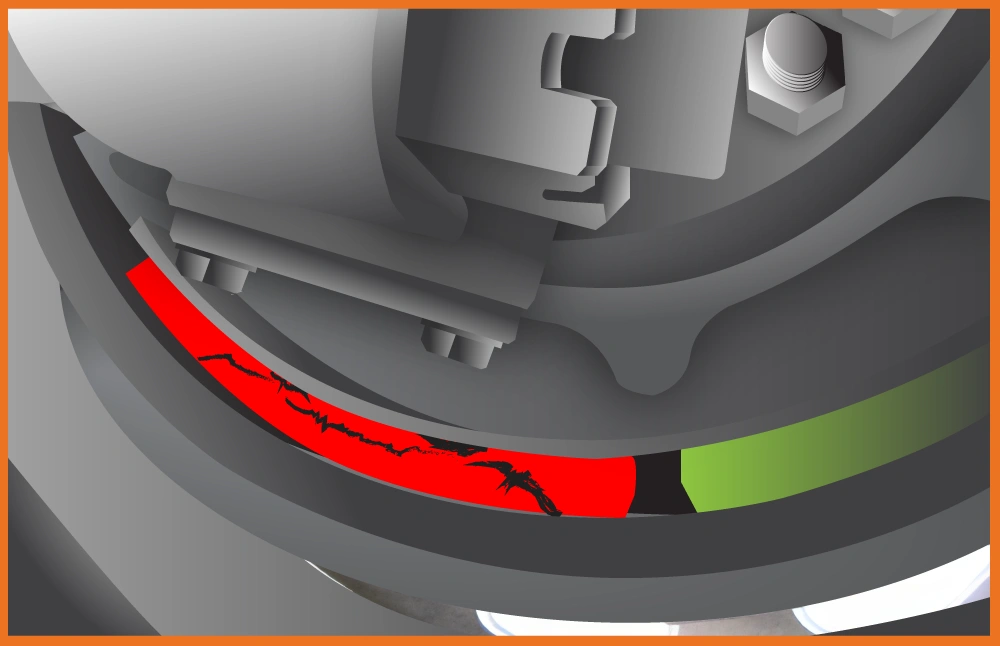

Check for visible cracks or voids in the lining block.

-

Check for any exposed rivets or lining blocks that look loose or worn out on the shoe.

-

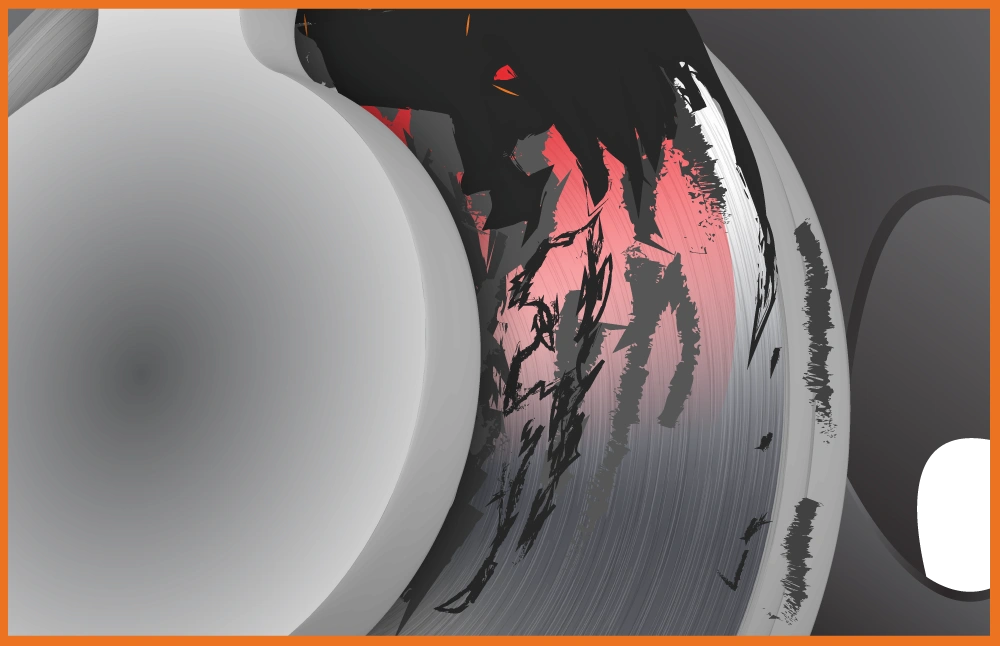

On disc brakes, pay particular attention to the condition of the rotor, such as heavily rusted rotors across the entire friction surface on either side or metal-to-metal contact.

-

Make sure all repairs are consistent with the brake manufacturer’s requirements and guidelines.

-

Note any issues in your driver vehicle inspection reports and report them to the motor carrier to have the defective linings/pads repaired.

Feel free to save the entire image for you records:

The Bottom Line

Well, there ya go! The most comprehensive guide to Brake Safety Week online. By following the guidelines and tips outlined in this guide, you can avoid picky inspectors and costly tickets while knowing your vehicle is safe. Let this guide serve as your roadmap to maintaining brake safety standards year-round. Brake with confidence this year and during Brake Safety Week.